Productive high-end machine

The TruMatic 7000 brings together the advantages of punch and laser processing in a particularly cost-efficient way. The high-end punch laser machine meets high demands in regards to part quality, productivity, and flexibility. With the active die, you can produce scratch-free parts and profit from the greatest level of flexibility when forming.

A new quality dimension

The active die provides you with scratch-free processing and new forming options due to the active forming stroke from below.

The best edge quality

The CO2 laser guarantees high-precision cutting results through outstanding beam quality.

Additional laser axes

The additional axes provide a clear productivity gain – right up to extremely high levels of productivity.

Automatic cutting nozzle changeover

The automatic nozzle changer removes the old nozzle for new orders, and inserts a new one, saving time in automated operation.

Safe removal

You can remove parts in a process reliable way via sensor-protected flaps.

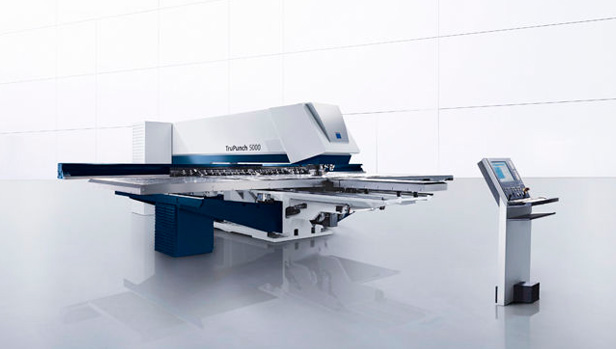

State-of-the-art and most powerful punching machine of the manufacturer Trumpf GmbH Germany, which ranks among the top manufacturers of such machines. The outstanding characteristics of the machine enable very fast and accurate production of the most complex products.

State-of-the-art and most powerful punching machine manufacturer Trumpf GmbH Germany, which ranks among the top manufacturers of such machines. The outstanding characteristics of the machine enable very fast and accurate production of the most complex products.

Top-level bending: even complex parts produced fast and accurately – with short setup times for maximum efficiency

The TruBend Series 5000 TRUMPF’s most successful bending machine worldwide. This means from programming, to setup, to bending, production productivity will be unmatched. Innovative features such as the lower tool displacement and the 6-axis backgauge provide you with complete production freedom. The operator’s work is made easier by numerous innovations such as the control concept, which is revolutionary in its simplicity and intuitive use, as well as new solutions in the field of ergonomics.

Quiet and fast

The On-Demand Servo Drive operates quickly, quietly, and in an energy-efficient way.

Angle measuring systems

With angle measuring systems from the Automatically Controlled Bending family, even the first part is a success.

User-friendly and ergonomic

Numerous equipment options make production more enjoyable, safer, and more productive.

Simple control

With the Touchpoint TruBend, operation is as easy and intuitive as with a tablet PC.

Automatic tool change

The automatic tool changer, ToolMaster, takes over all tool setup operations.

Flexibility due to 6-axis backgauge

The 6-axis backgauge provides you with complete freedom in use.

The electric bender enables extremely fast, and above all, high-quality bending of products that must be manufactured within a very narrow tolerance range..

With the help of a compact and reliable machine, a wide variety of screws, nuts, and bushings can be pressed or attached into the sheet metal, greatly facilitating final assembly.